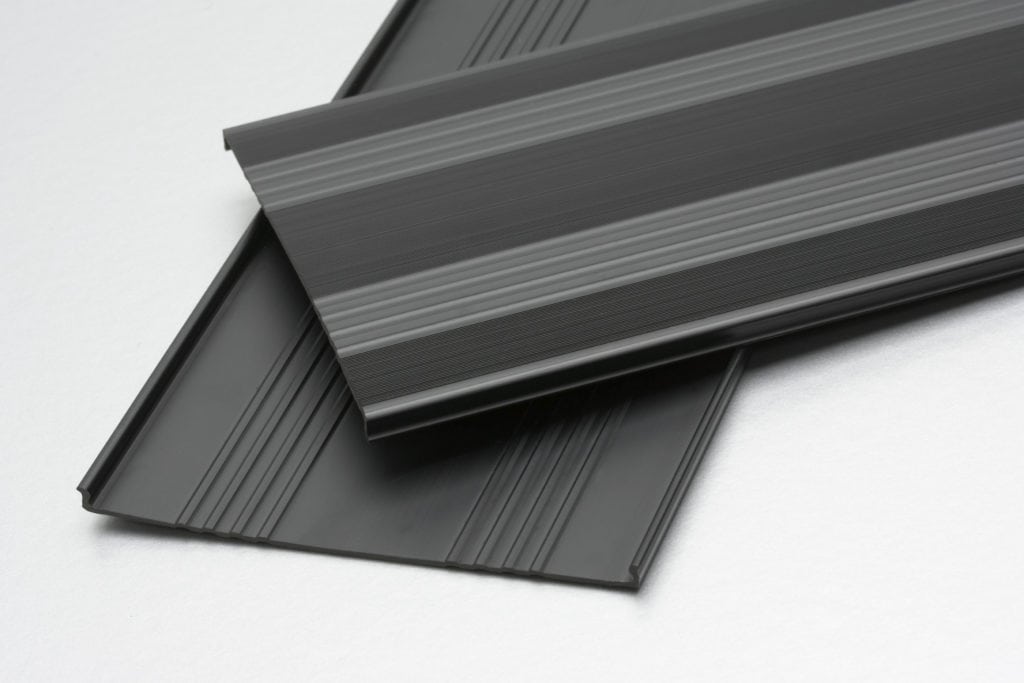

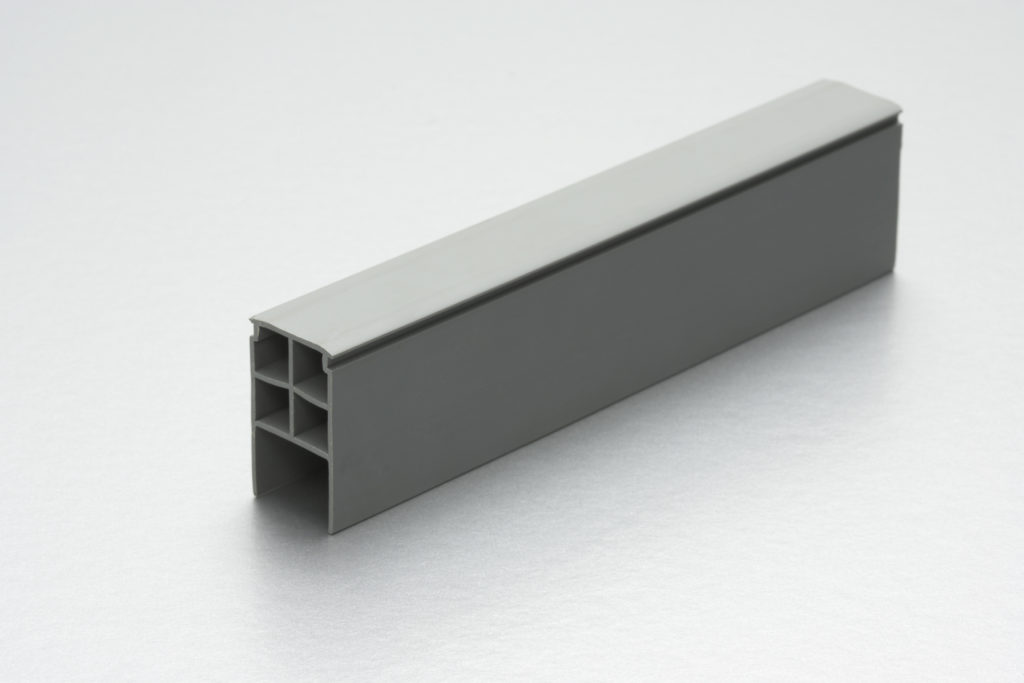

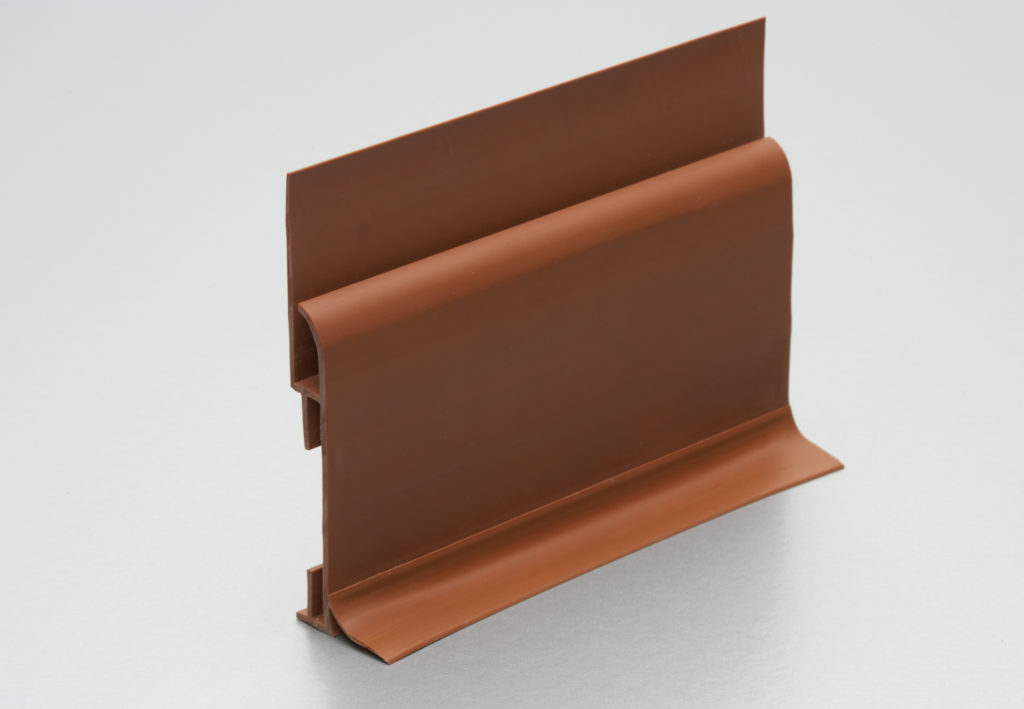

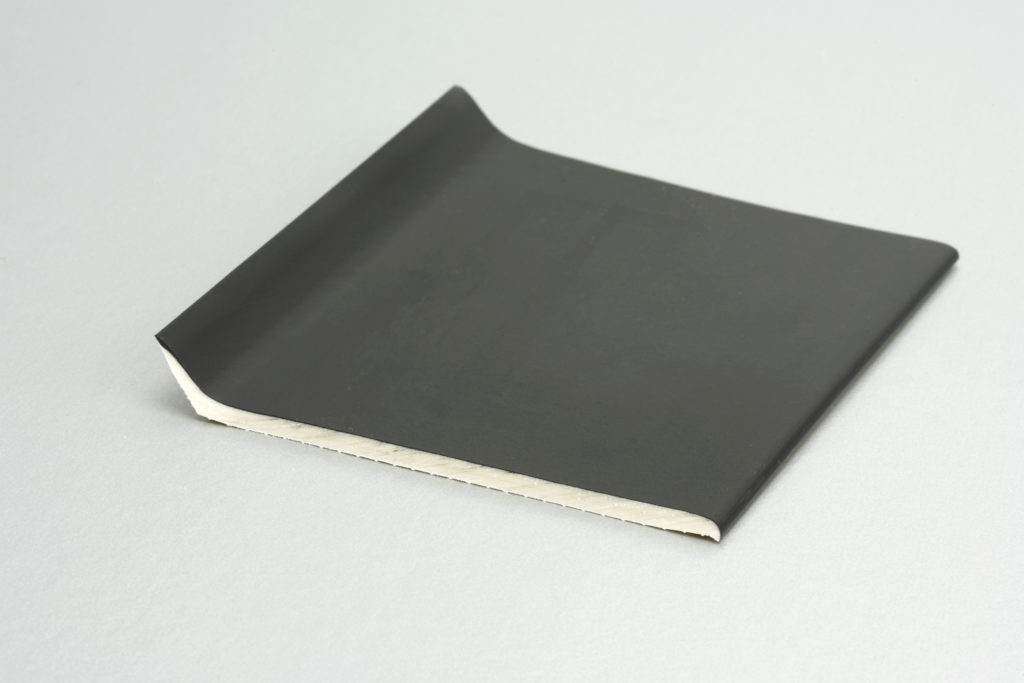

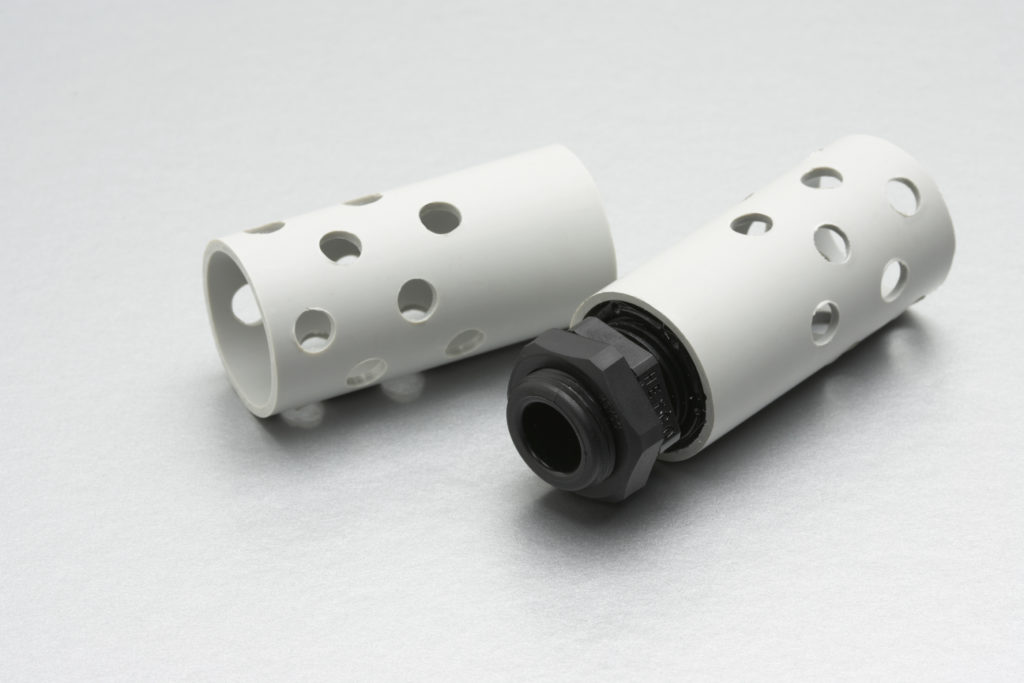

Custom Profile Extrusion

Here at Profile, we extrude a wide range of profiles from simple tubes to complex parts with multiple hollows and critical tolerances. With a variety of machine capacities available, we produce small or large parts and run at conservative or aggressive rates depending on your volumes, precision required and cost objectives. Customers from many different industries seek our ability to meet their specific needs, and many of Profile’s parts are those that others were unwilling or unable to produce. We are willing to evaluate any challenge. Let us have a look at your current opportunities and see how we can help you achieve your objectives.

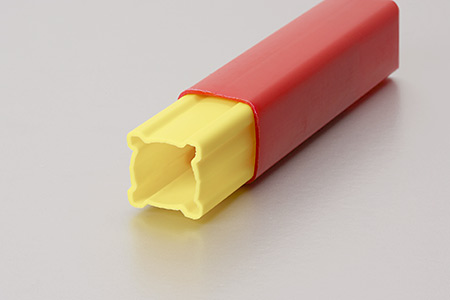

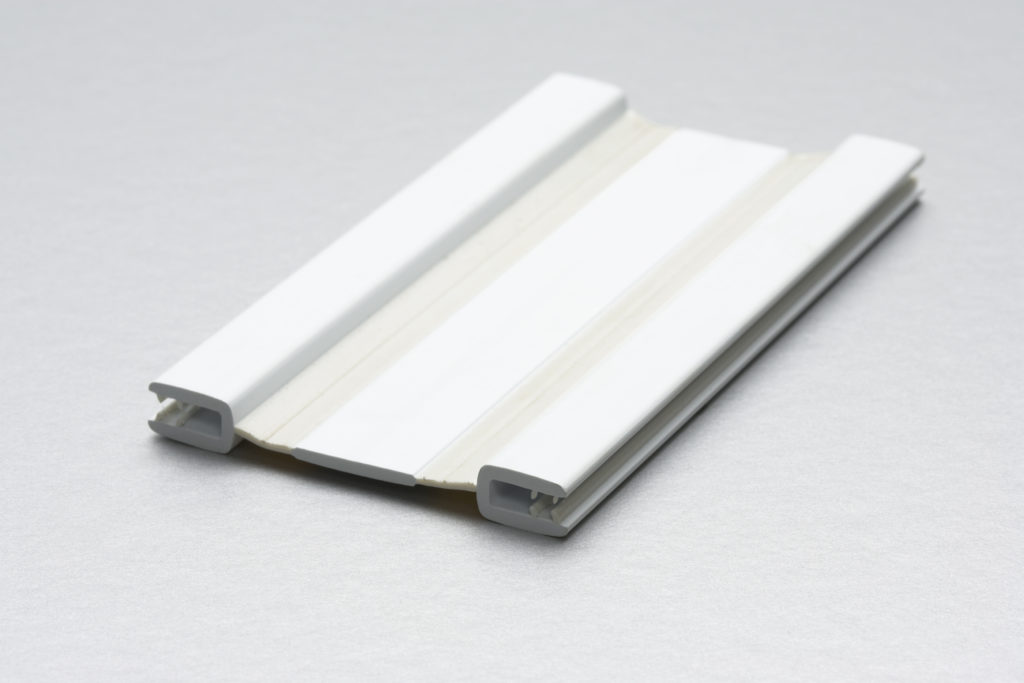

Coextrusion

Profile has experience with a variety of coextrusion applications. Cap stock applications can reduce costs by using a low cost back layer with a high performance top layer for color, durability, flame retardance, weatherability or other attributes. Flexible sections can be included in your part to provide hinge areas, integral seals, sewn attachment areas or multicolor parts. Profile integrates multiple sections in your part for each material, and can combine three or even more materials for triextrusion and beyond. We help you choose from a variety of materials to ensure good adhesion and meet your needs including vinyls, thermoplastic elastomers (TPEs), thermoplastic vulcanizates (TPVs) and thermoplastic polyurethanes (TPUs) with a variety of rigid substrates.

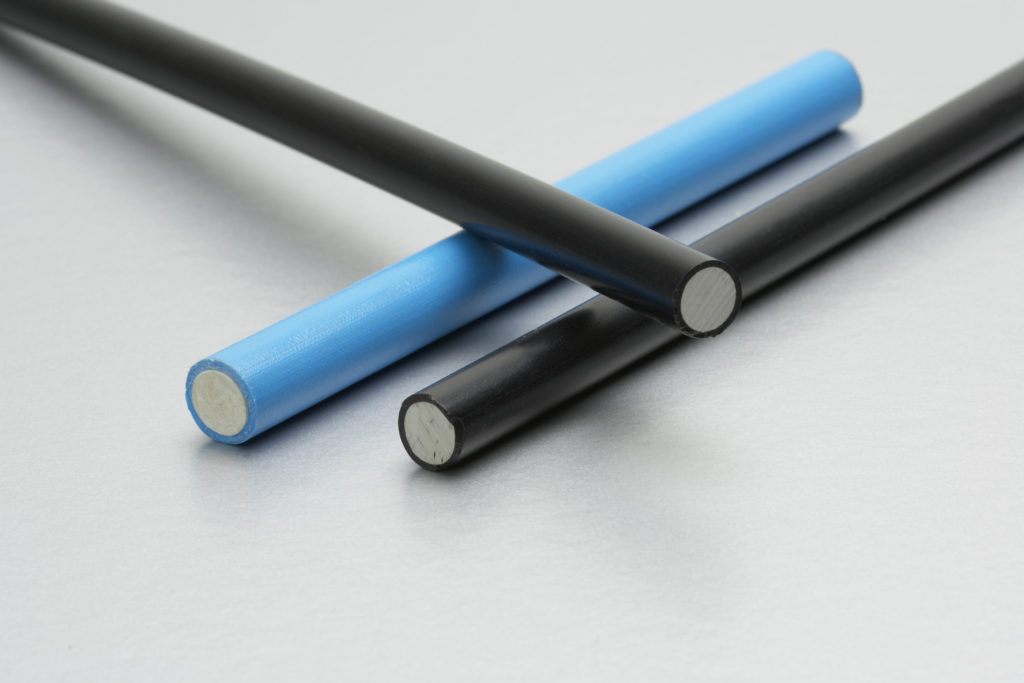

Cross Head Extrusion

Profile Plastics manufactures plastic extrusions with a variety of components embedded in the part. This can allow for function and performance typically unavailable in simple extrusions. Creep or stretch resistance, enhanced rigidity or electrical transmission are examples of cross head extrusion benefits. If you need a conductor in your extrusion, we can include various types of wire including flat or other shaped wires. Profile processes reinforcement like fabric scrim to reduce elastomer stretch, metal and fiberglass for added rigidity and threads to reduce creep. We can apply multiple layers of coating to your products. Whatever your application, we can assist.

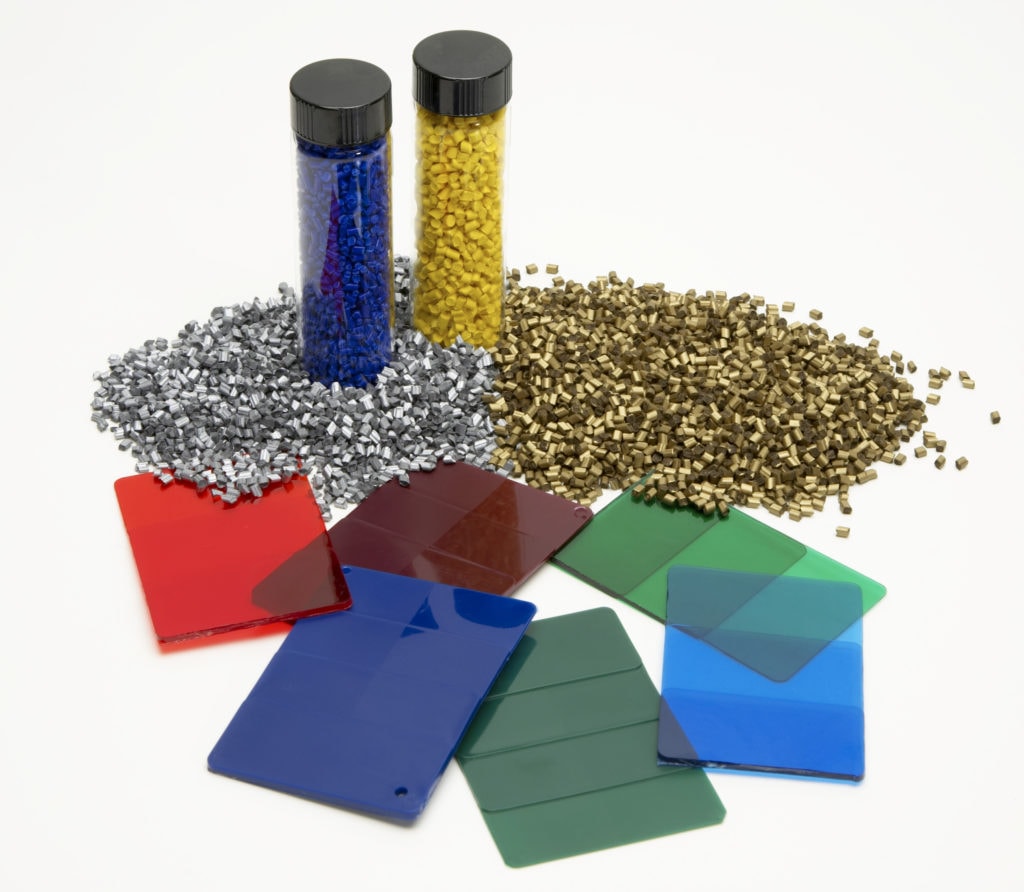

Materials

Profile extrudes many different materials from basic commodities to highly engineered polymers developed for specific applications. We offer nearly any material required to deliver the performance you need. Profile’s suppliers support applications that require a custom material formulated to meet the specific needs of our customers. If the best material for your application is something we have not processed before, we always welcome a new opportunity.

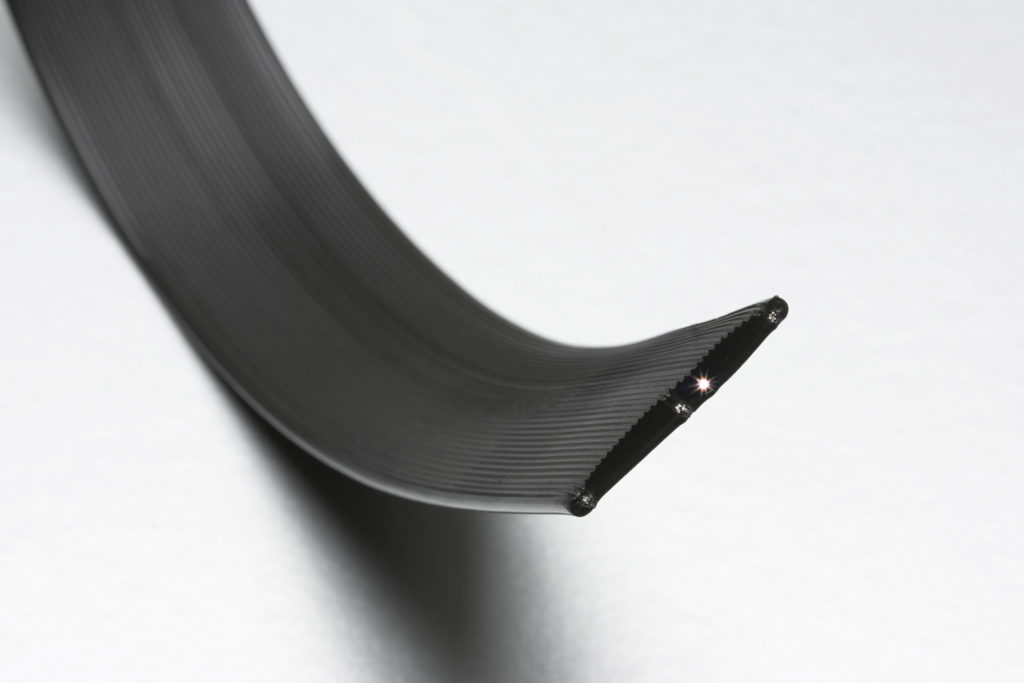

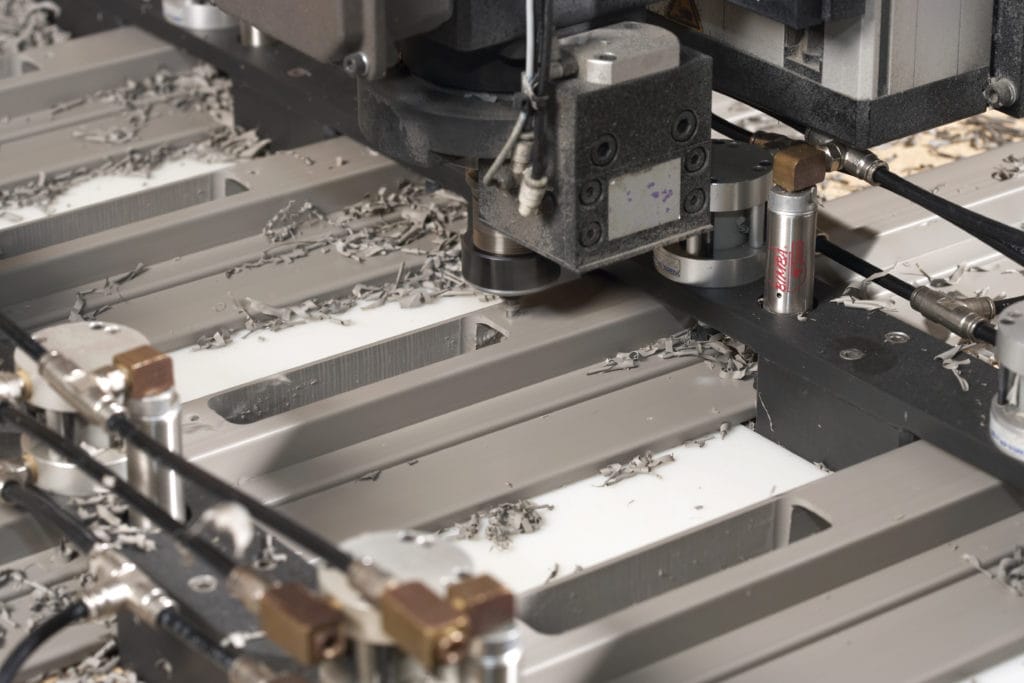

Value Added Services

Once your part design is complete, we examine how your parts are used. If your parts will need any additional operations, fabrication or assembly, we can assist. That could include tape or adhesive application, printing, embossing, punching or drilling, CNC machining, bending or welding. And Profile can perform many of those operations as we extrude to save you time and money by streamlining your processes. We will discuss packaging with you to ensure your parts are protected and easy to store, handle and use. We provide custom packaging or special labeling when needed. Profile can package and label your products in shelf ready retail packaging or assembled into kits with other components ready for your customers to use. Ask us how we can deliver extra value for you.

Application Assistance

Profile can assist you to bring new designs to fruition, improve current parts or help you reduce costs. We help you select materials that meet the needs of your application. This may include UL listings, temperature resistance, impact resistance rigidity and other attributes. Profile works with you to understand your application and help ensure your parts perform as required. Our team offers suggestions to provide functional extrusions for your end use. Together we ensure your product performs to expectations with the right balance of cost and performance. Once we understand your parts, our experienced tooling team transforms that understanding into finished parts. Our on-site tool and die shop also designs, builds and programs the fixtures and equipment necessary for efficient and reliable fabrication and additional processing of your parts.